Our vision: To build industry changing solutions that create

life-changing opportunities.

Welcome To Astec

Coming Together as OneASTEC

Sixteen brands, thousands of Innovative products, proven by a century of work. With unmatched strength from Rock to Road. Connection is at the heart of everything we do. We design and manufacture products used to build the infrastructure that physically connects the world, but the connections we make with people are what drive us forward. We were founded on innovation and a passion to help our customers succeed. It’s this commitment that has driven our decision to unify as one company. ASTEC. We’re simplifying the way you do business with us. We’re focusing on our customers’ success. And we’re committed to growing as a partner to the industries we serve. At ASTEC, we are Built to Connect...

Find out more about our products

OUR BUSINESS LANDSCAPE AND MARKET PHILOSOPHY

ASTEC was founded in 1972 with the vision to apply creative thinking and state-of-the-art technology to traditionally low-tech industries, bolstered by a corporate culture renowned for putting customer service first. Based in Chattanooga, our market-leading brands have become a global leader in the manufacture of equipment from Rock to Road.

OUR CORE VALUES

- Safety

- Devotion

- Integrity

- Respect

- Innovation

OUR MISSION

Ultimately, our goal is to design and build state-of-the-art equipment which makes it possible for our customers to supply their customers with industry leading results profitably.

For our customers, we will continue to be the most innovative company in our industry offering the world’s most advanced, productive, durable and environmentally friendly products, coupled with training and education, service and support that is far beyond anything offered by our competition.

For our shareholders, we strive to deliver continuous increases in shareholder value through stable long-term growth in earnings per share. To that end, we plan to expand and enhance the scope and profitability of our core business through internal growth and strategic acquisitions.

For our employees, we aim to provide a safe and welcoming work environment where they are empowered to ask questions and make suggestions for improvements from operations to sustainability. With Safety as our first core value, we regularly invest in training, personal protective equipment, and technology to continuously improve our safety programs and “Strive for Zero Harm.”

ASTEC

1725 Shepherd Road

Chattanooga, TN 37421

Phone: +1.423.899.5898

Fax: +1.423.899.4456

Our Locations

Astec Industries News

-

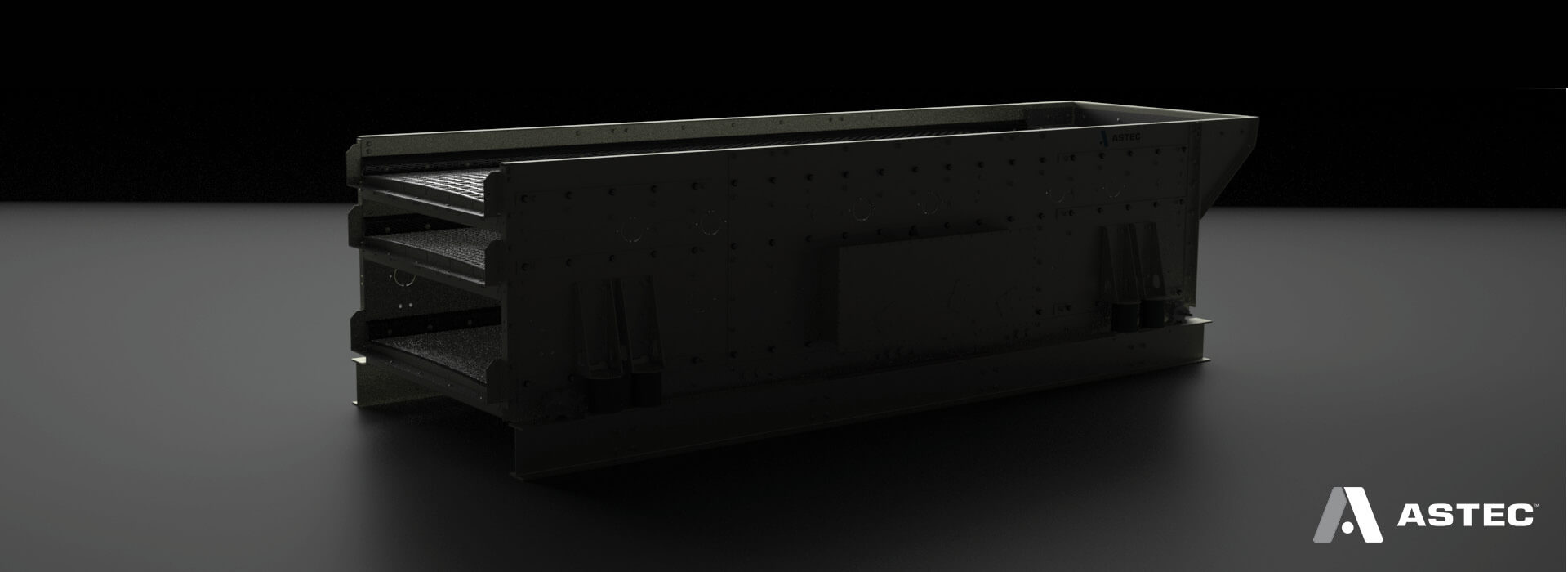

Astec Showcases Revolutionary Screening Technology

Astec Industries (NASDAQ: ASTE) showcased its prototype Vari-Frequency™ screening technology in March at the World of...

![]()

-

Astec Industries Announces Expanded Concrete Equipment Offering Through Dealer Network

CHATTANOOGA, Tenn., April 1, 2024 – Astec Industries, Inc. (NASDAQ: ASTE) today announced a strategi...

![Concrete Dealer Announcement]()

-

Astec ReMix™ Cold Central Plant Recycling System: Revolutionizing Sustainable Road Construction

Astec Industries is proud to announce the release of its Astec ReMix™ Cold Central Plant Recycling (CCPR) System. This c...![Astec Remix CCPR]()

-

Introducing the Astec IntelliPac™ Moisture System: Unparalleled Visibility Into Aggregate Moisture Levels

Introducing the Astec IntelliPac™ Moisture System, an innovative solution poised to revolutionize asphalt production by ...![]()

-

Astec Set to Showcase Cutting-edge Milling Technology at World of Asphalt/AGG1 Expo 2024

Astec to showcase the RX-405 cold planer at World of Asphalt/AGG1, March 25-27, 2024 in Nashville, TN, which will includ...![Roadtec RX-405 Cold Planer Banner]()

/ranger-plants/ranger-line-header-02.tmb-nav-cards.jpg?sfvrsn=c145462e_3)